DEEMY

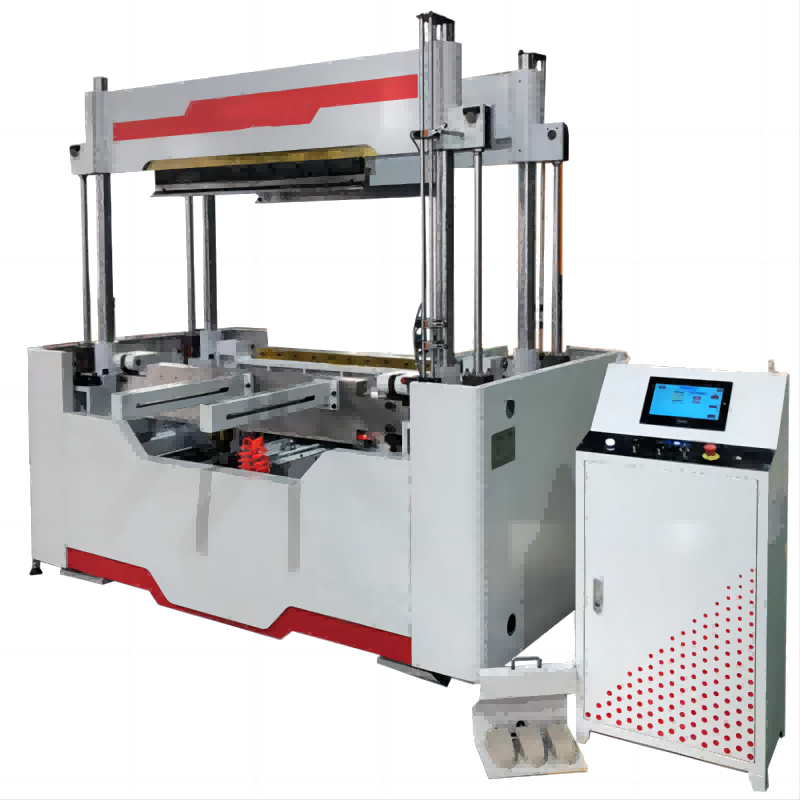

CNC DOUBLE BENDING MACHINE

CNC DOUBLE BENDING MACHINE

无法加载取货服务可用情况

1.Performance Characteristics

All the main parts and accessories of this machine are developed and designed by the company, and the main structure of the machine is automatically simulated and calculated by the computer PRO/E 30 latest version of the mathematical trigonometry

function precision program. The tensile strength and compressive strength of the main structure and the parallel line of the table are all within the safe range.

This machine adopts 02358 material steel plate, and all the joints of the steel plates are cracked to ensure the strength of the whole machine.

The whole machine is annealed and stress relieved, which ensures rigidity, strength, precision and structural stability.

After the machine is annealed, it is sandblasted to remove rust and treated with anti-rust spray paint.

After the structure of the machine has gone through the above process, the machine is processed and formed at one time with a large-scale precision gantry milling machine to ensure the parallelism and verticality of each installation part.

X-axis is a high-precision moving side, equipped with two sets of Taiwan Shangyin high-precision linear motion linear slide rails precision ball screw drive, high-precision servo motor drive, and linear plane slide rails for the guide rails. The positioning is fast and accurate, and the operation is noiseless and moving. it is convenient for the bit to return to zero smoothly.

Electrical, electronic components and materials are in line with ISO. CE and EMC standards, electrical and electronic equipment is safe and reliable, long service life, strong anti-interference ability.

The control system is easy to operate, has reliable safety protection function, and the equipment has safety protection interlocking device to prevent equipment damage and personal injury from accidents. Once an abnormality occurs, the power supply of the equipment can be cut off conveniently and quickly. After the abnormality is eliminated, the system can be put into normal use quickly.

2.Main Specification

|

Name |

Unit |

Main Specification |

|

Processing plate thickness |

mm |

0.5-2 |

|

Length of processing plate |

mm |

1260 |

|

Width of processing plate |

mm |

1000 |

|

Move edge(x axis) |

mm/s |

0-200 |

|

Moving edge (Y1, Y2 axis) |

mm/s |

0-50 |

|

Flap (R1, R2 axis) |

mm/s |

0-50 |

|

X-axis machining accuracy |

mm |

±0.01 |

|

Machining accuracy of Y1, Y2 axis |

mm |

±0.01 |

|

R1, R2 axis accuracy |

/ |

±0.5 |

|

X-axis motor power |

KW |

2 |

|

Dimensions |

mm |

2400×1600×2400 |

|

Equipment weight |

KG |

3000 |

|

Flatness of table |

mm/M |

±0.02 |

3.Main Configuration

|

Name |

Product Name |

|

linear guide rail |

Rexroth, Germany |

|

ball screw |

Taiwan TBI |

|

servo motor |

Yasukwa or Mitsubishi, Japan |

|

Electrical components |

Schneider, France |

|

Hydraulic system |

Nippon Yuken |

|

Numerical control system |

Independent research and development |

|

Oil pump |

SUNNY Sunny, USA |

|

Main motor |

Siemens, Germany |

|

Proximity switch |

Omron, Japan |

|

Cylinder |

Jiangsu Yongjian |

|

Tool |

Anhui Union |

4.Specifications

|

Model |

Bending capacity |

Minimum angle |

Bending angle |

Main motor |

|

ADS-860 |

2 |

60° |

Any angle |

3HP |

|

ADS-1060 |

2 |

60° |

Any angle |

3HP |

|

ADS-1260 |

2 |

60° |

Any angle |

3HP |

|

ADS-1560 |

3 |

0° |

Any angle |

3HP |

Movable leaf assembly drawing Examples of finished products

Share