DEEMY

CNC BENDING MACHINE2

CNC BENDING MACHINE2

无法加载取货服务可用情况

1.Performance Characteristics

The fuselage is designed through finite element optimization to ensure that the machine tool has high strength and high rigidity when it is used.

Compared with the traditional CNC bending machine, the flow rate of liquid filling and the displacement of the oil pump are increased, and the movement frequency of the Y-axis is about 25% higher than that of the mainstream bending machine in the market.

The use of high-frequency proportional valve ensures that the machine tool has high stability and high precision in the process of high-speed operation.

The closed height, throat depth, slider stroke, etc. are increased, which is convenient for bending and taking large workpieces and more complex workpieces.

The standard mechanical deflection automatic compensation system can solve the influence of the deformation of the slider on the quality of the workpiece during the bending process, which is convenient and accurate.

2.CNC System

High resolution 10.1"full color LCD wide screen display.

Industrial grade PCT toughened glass touch screen.Anti-scraping and gloves operation.

The internal storage capacity is 1GB,and the material can be edited up to 99.

Support flanging,big arc,one page tabular programming,support product search.

3.Mechanical Compensation Device

The mechanical compensation is a bidirectional wedge adjustment structure,which can meet the horizontal and vertical compensation adjustment of the machine tool;

The structure adopts the way of dense point compensation, which makes the bending accuracy more accurate;

Different from the hydraulic compensation structure;

mechanical compensation can greatly reduce the fatigue deformation of the machine tool worktable and improve its service life.

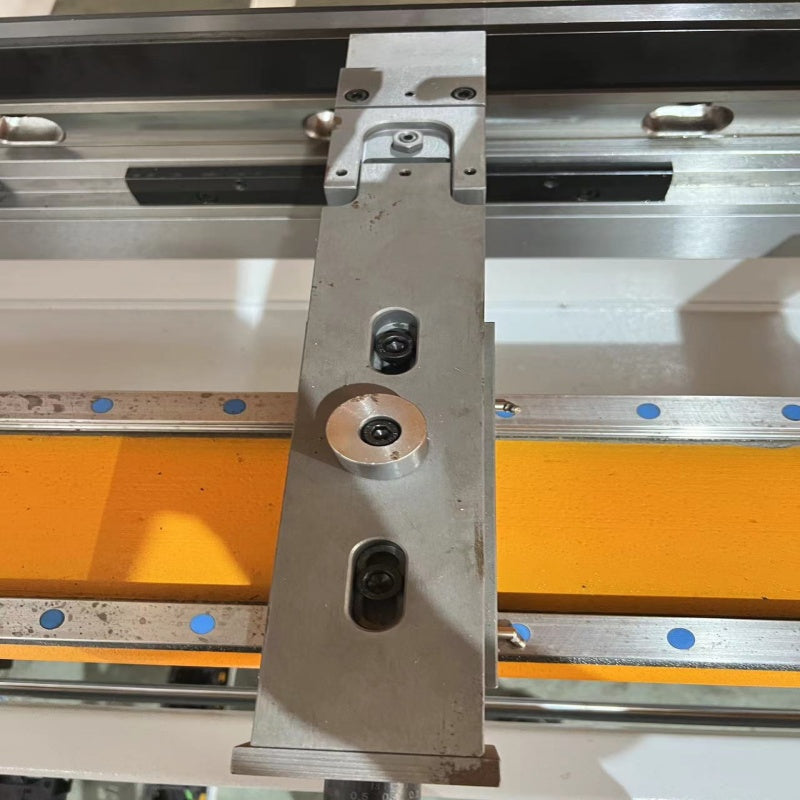

4.Heavy Duty Back Gauge

Accurate and stable rear stopper device,servo motor driven ball screw,fast speed and high positioning accuracy;Multi level gear design,increased positioning range,and value for money;Modular design,the number of control axes can be selected from single axis X to multiple axes.

5.Main Specification

6.Main Parts

Hydraulic System (standard configuration)

The integrated German Rexroth hydraulic control system is adopted to simplify the pipeline,prevent leakage,improve the working stability of the machine tool,and make the appearance more concise and beautiful.The use of internal gear pump made in Germany or Japan ensures low noise and long service life of the whole system.

Bending Machine Cylinder (standard configuration)

The electric-hydraulic servo system can control the synchronization of two cylinders.Combined with magnetic displacement sensor of international standard,the fully closed loop controls formed with high synchronization control accuracy,and high bending and repetitve positioning accuracy.

Siemens Main Motor

High efficiency,energy saving,reliable operation,convenient maintenance, good cooling effect at different speeds.

Clamping (standard configuration)

The punch quick clamping can be made based on the customer's requirement to

Heavy-duty Mobile Front Bracket

Equipped with heavy mobile front bracket,reduce bending labor intensity,improve production efficiency.

C-Type Throat Compensation Device (standard configuration)

The device is installed at the bottom of the throat of the machine tool [Standard configuration],which is connected with the magnetic gate ruler,so the stress and strain of the machine will not affect the precision of the measuring element,so that the bending precision of any thickness and any material sheet will be ensured.

7.Optional Part

Mechanical Compensation Device(optional)

The mechanical compensation is a bidirectional wedge adjustment structure,which can meet the horizontal and vertical compensation adjustment of the machine tool;

The structure adopts the way of dense point compensation,which makes the bending accuracy more accurate;

Different from the hydraulic compensation structure,mechanical compensation can greatly reduce the fatigue deformation of the machine tool worktable and improve its service life;

Special reduce and high-precision potentiometer are used to control the compensation precision accurately;

Different from the three plate structure of the hydraulic compensation worktable,the device adopts the single plate worktable design,which can effectively prevent the interference in the bending workpiece.

Light Mobile Front Bracket Device

New design movable front support device,linear guide slide,fast and convenient.

Safety Light Curtain

Class 1 m laser circle without damage to human eyes.

The safety level is cat, 4 and sil3, and the protection level is lP65.

The receiver is equipped with LED indicator to display various states in working mode.

The minimum speed transition point is 5 mm.

The protection distance can reach 15 m.

There is almost no interference of the bending machine under the protection of the tool tip.

Stable performance,same life as bending machine.

Communication with bending machine system.

Double-sided Quick Clip(optional)

Positive and negative dual-side quick tightening device,to meet the requirements of customers' positive and negative sides tooling installation which ensures the bending of special work pieces.

Vera Automatic Hydraulic Clamping Device(optional)

Tooling auto clamping,setting and calibration,Quick tooling replacement,Saving 70% installation time compared with others.

Backgauge System

The large lead ball screw and linear guideway from international famous company ensure the positioning accuracy of the machines. The full functional backguage system can be extended up to six axis,The workpiece can be bent at whatever angle.

CNC System

DA53T System

High resolution 10.1"full color LCD wide screen display.

Industrial grade PCT toughened glass touch screen.Anti-scraping and gloves operation.

The internal storage capacity is 1GB,and the material can be edited up to 99.

Support flanging,big arc,one page tabular programming,support product search.

DA66T System

2D touch graphic programming

3D product graphic simulation display

memory capacity 1GB

USB peripheral interface

17 "high resolution TFT true color display

CT8 System

High definition and contrast touch screen system

Convenient interface,clear display and big icon button

Perfect programming can improve the efficiency of batch multi-step bending

Online help and pop-up prompt make the software interface very friendly and support

multiple languages

The PC or notebook can be used to upgrade and transmit data through wireless software

CT12 System

Multiple automatic calculation functions of bending sequence

It can store multi-step bending steps and products

Angle,pressure and compensation control

Automatic calculation is allowed for bending

Angle and back stop correction

Wireless remote connection system via P© or notebook

Share